BOW & ARROW

August 1980

Howard Hill Big Five Longbow – Bow Test

HOWARD HILL was a legend long before his passing in

February of l975. He was the man who started my

generation shooting the bow and arrow. And we all began

with some form of the longbow, however humble the particular model happened to be.

We young enthusiasts sometimes had the great good luck

of catching Mr. Hill in one of his short films. For a quarter,

our parents could get rid of us for about a half-day at the

movies, with a cartoon, sometimes two, a main feature and

a serial calculated to keep us in suspense and to return next

Saturday to see how Flash Gordon made out against the

evil forces of Space.

In between the feature and serial, we often had a “select-

ed short subject.” Sometimes they were dull, and l suspect

that an educator in the community was bribing or threatening

the theater manager to slip these in. But one afternoon,

the short was anything but dull. It was Howard Hill himself,

doing things with a bow that didn’t seem possible to us.

The gang was already into some form of archery, but it

was Hill who drew us away from the horrible mismated

archery tackle to balanced tools. My first bow, in fact, was

an oleander limb whacked off of my grandfather’s hedge, a

stretch of packing twine for a string and milkweed reeds for

arrows. Self-bows were next. They were often lemonweed,

and not all that bad, but too thin of core and too flat of

limb. They only cost a few bucks to buy and arrows for

them were twenty-five cents. Mine drew around twenty-five

pounds. I still have it.

The yew bow was a romantic and suitable model. But

back in these carefree days of the twenty-five-cent movie

in the l950s when this writer was a ripe IO years old we

began to tune in on the Hill archery song the handsome bows

with matched equipment to go with them, longbows. By

way of definition, these bows were indeed long, certainly

sixty inches and more often sixty-six inches and more, and

they were thick of core and narrow of limb with graceful

tips to nock the string.

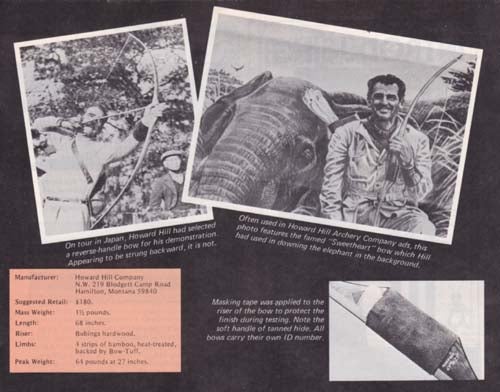

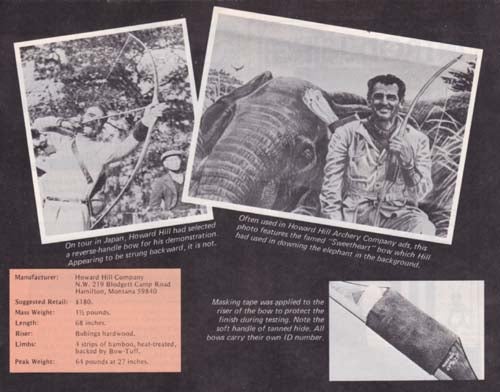

The Howard Hill Company of Hamilton, Montana, is and

has been offering a replica, as it were, of the Hill-style bow,

and the particular model which crossed my hands for a test

run was their top-of-the-line Big Five model. The Big Five,

according to the literature and information given me by Mrs.

Betty Ekin, friend of Howard Hill and, along with son Craig,

operator of the Howard Hill Archery Company, was patterned

after the famous “Sweetheart” bow of Hill’s.

This top-of-the-line model is the one I preferred to test,

as I try to do with all companies’ bows. The construction of

the bow is per Hill’s design. That is, the core is bamboo.

Anyone who looks into the older books referring to Hill’s

bows will recall that Howard preferred bamboo for his limb

laminations. The current Hill Company has followed suit

and is still using the particular bamboo which Hill deter-

mined was best. Those of you who may, perhaps, flyfish,

may be familiar with the “temper” and action of the more

expensive “split bamboo” flyrods. The same criteria of

action and resiliency which make a flyrod “alive” also make

the longbow feel alive in the hand.

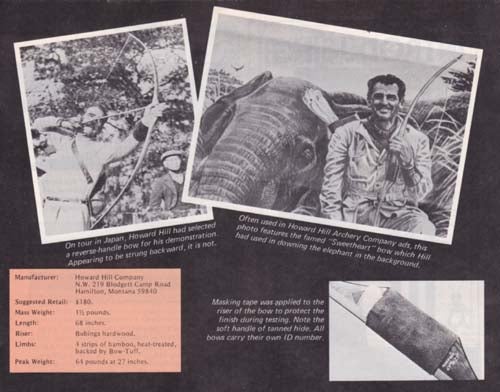

The specific type of bamboo, of course, is important as

all bamboo is not created equal. Hill reportedly took a trip

to Japan in 1960 in order to find and ship home a specific

species of bamboo he found most suitable for his needs, and

I am told that the Hill Company still uses this species in the

bow’s construction to date.

Obviously we are speaking of the heart of the bow when

we talk bamboo. This heat-treated bamboo, which of course

has been split into thin lengths, is then laminated together

to form the thick, but narrow core of the true longbow type.

As a simple matter of rule, I noticed that the Hill’s bows rank

according to number of laminations, the top of top-of-the-line

Big Five having four strips of bamboo, the Tembo with three

and the Half Breed with two. I cannot say that the bows with

only two laminations or three, are not fine-shooters too, because

my previous tests show that they are; however, the price being

reasonable anyway, the Big Five is surely one to look at as

a bargain.

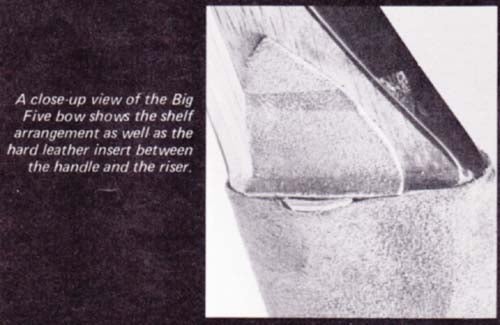

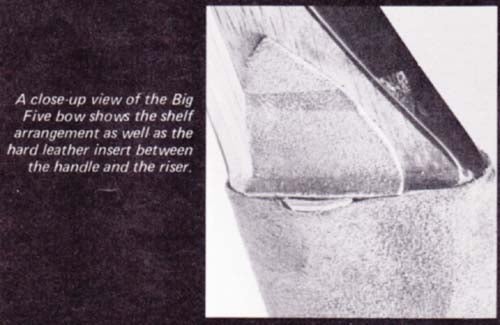

The Belly and face of the bow are both backed by glass on the

Big Five, in this case, Bow-tuff, a brand with which we are all

familiar. The riser is Bubbinga hardwood, another material we all

know well. Though not an elaborately beautiful wood, Bubinga is

a sturdy and entirely suitable in the longbow. The traditional longbow

riser is going to sport a handle of tanned leather anyway, covering

most of the wood. The shelf of the bow consists of a small hunk of

very hard tanned hide which is tucked underneath the leather handle.

Another piece of hide is used against the side of the handle

where the arrow would make contact.

Shooting off the shelf is, of course, standard practice

with the longbow, and it sometimes bothers those who have

not tried this type of bow. It should not. Shooting off the

shelf works fine. If a very special arrow rest were attached to

the bow, there is no doubt that a few foot-seconds of speed

would be picked up, but shooting from the shelf offers fine

control and very easy handling of the shaft from nocking to

controling during the holding of the bow at fulldraw. l prefer

to shoot off the shelf with a longbow and will not attach

a rest to one.

The nocking ends of the bow are traditionally pointed and

very lean. And, contrary to the way things might look,a long-

bow tends to remain strung admirably well. l have never in

my life had one become unstrung in the act of shooting, in

fact, and I have shot a good many longbows. There is an enforcer

strip of glass laminations on both ends of the Big Five.

This is a sandwiched piece of glass that tapers thin.

The final finish of the bow is excellent with the exception

of a couple places where it looks as though there was an

epoxy run, or lumping of final liquid finisher. The widest `

part of the limb is about 1 1/4 inches. That will i seem slim to

anyone used to the limbs on a compound, and it is also

quite narrow as compared with the recurves of the Fifties

and Sixties that were sold primarily over the counter. It is a

matter of what fits where, and the narrow limb on the long-

bow is a plus factor, The core, that is the thickness of the

bow as viewed from the side upward from the riser and down

from the riser, is thick, in this case about seven-sixteenths-

inch at the widest measure.

The particular longbow that I elected to test turned out

to be a draw weight of sixty-four pounds thrust at twenty-

seven inches pull. I would have preferred a seventy-pound

draw at twenty-eight inches; however, I did overdraw the

bow by one inch in the test so that I ended up with a force

of sixty-seven pounds. This was close enough, as I do like to

keep all my test bows within a range of about seventy pounds

pull. Overdrawing is not the best practice in the world, by

the way, but for the few shots I had to fire over the chronograph

screens, plus less than fifty darts tossed at the targets,

the bow was not in any sense harmed.

All in all, those are the physical characteristics of the

Howard Hill Company’s Big Five longbow. However, the

reader may be curious about the name itself. As already

stated, the Big Five is a direct copy of the old Sweetheart

bow of Hill’s, and it was that bow which went on the famous

safari after the “big five” of Africa. Hill took three elephants

on that trip, I am told, firing four arrows for all three

from his 115—pound bow. Back in the Fifties, when the feat

was fresh, wild stories flew all around the archery world that

Hill had used a 150-pound bow and so forth, but it was the

II5-pound model that did the trick, firing special forty-one-

inch arrows.

Hill’s bows were set up for a twenty—eight-inch draw, I do

believe, and that has been considered a standard for many

years. While Hill was not a weight lifter, he was a powerful

man who had a good set of arms on him, However, he apparently

credited his ability to totally master the eighty,

ninety and one hundred-plus-pound bows to building up to

them. Naturally, a whole different set of muscles apply to

drawing the bow, and I have seen many a strong man shudder

and shake trying to draw a bow of far less than eighty

pounds pull.

Hill did not advocate going to heavy bows that were not

manageable by their owners. Of course this is correct, but

we should not misconstrue the statement as some have. Hill

was not in favor of sticking with a light bow just because it

could be easily mastered. He elected for the heaviest bow a

person could shoot with comfort. That means, he wanted us

to build into our bows, finding a place where we could

master a given poundage.

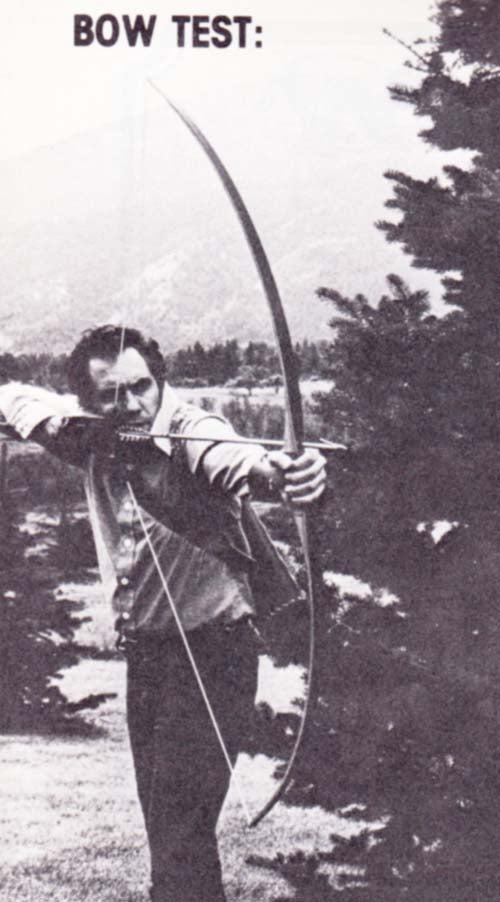

In shooting the longbow, it is difficult to explain how

to aim one. I have never had any luck trying to tell some-

one how to hit a target with a longbow, although Hill at-

tempted to teach a split-image design of aiming. I am not

certain that is what he called it, but the term seems to be

correct. Simply, a longbow is fired-pretty much the way

we toss a rock. A rock has no sights. And yet I’d bet that

no one reading this would have any trouble coming pretty

close to a tin can at ten feet, thirty feet, twenty yards;

even much farther. And·we have darn little practice at

rock throwing, too.

Since there are no sights on the longbow (although

there certainly have been sights on some longbow models

out of the past) it is best to grab up the bow, nestle the

hand comfortably into the leather grip without choking

the grip down, and then moving the bow around a bit to

get the feel of it. Remember, the entire mass weight of the

Big Five is only one pound and six or so ounces.

The bow can be held without undue strain in the bow-

hand, by the way, as the handle wedges back into the palm

just as with any other bow type, and this is the best way

to shoot, without choking down on the grip. The same

anchor point the archer uses for his compound may not

be fitting for longbow shooting, although I find no problem

using the same point. The left arm is somewhat crook-

ed in drawing the longbow and the archer leans into his

work, rather than standing straight up. The bow is usually

canted, or tilted off to one side, which not only aids

in maintaining the arrow balanced on the shelf, but also

allows for the head to be bent a little, too. The bending

of the head puts the eyes in line with the shaft and the

target.

All I can say is that something unconscious soon takes

over and the archer is popping arrows into the target butt.

I like to think l keep my eyes on the target and not the

tip of the arrow, but I am told by smarter men than l

that the eye does dart back and forth from target to

arrow tip. I am not going to consciously try to discover

whether it does or not. `

The fistmele on this bow will be terribly small by the

standards of the old recurves and the modern compounds.

In fact, shooters may have trouble with this, sometimes

turning the riser so that the string snaps into the arm.

Naturally, it is wise to use an arm guard But the shooter

should not try to make the fistmele dimension wider. It

will normally slow the bow down and decrease the cast

and sometimes upset the arc of the arrow. The fistmele

is properly short, and on my test model it was only 5 3/4

inches from the back of the riser to the string.

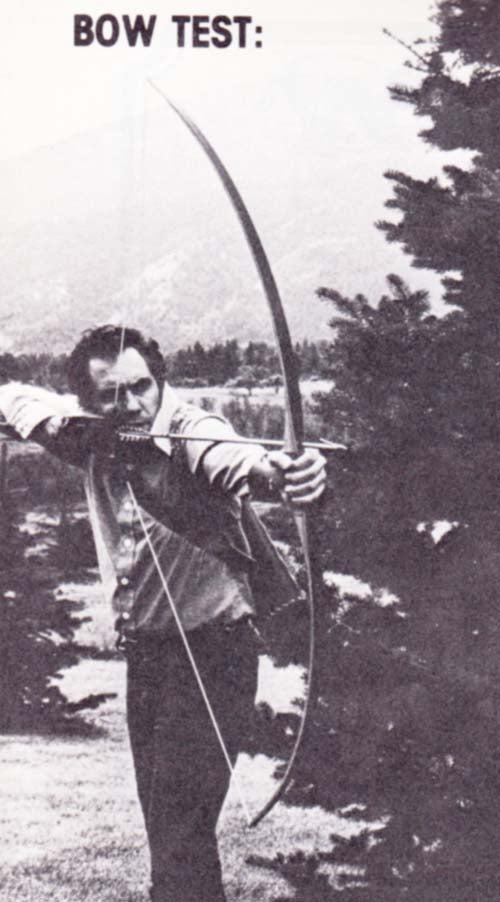

The riser is standard on the Big Five. That is, it points

inward to the hand as per normal/average. However, Hill

did use some models which were reverse handle. I have

such a bow and I am forever asked “Why did you string

your bow backwards?” It is not strung backwards. The

handle is fitted that way to offer a different type of grasp

for the hand.

In stringing the Big Five, I used my stringer. That

makes sense to me. I never did care for the step-through

method, because even with a stable-limbed longbow, a

twisted limb is still a possibility. There is also the push-

away method, and that works all right. I may not have

developed the particular muscles necessary to master

the latter, and with my own seventy-pound longbow, I

have a hard time stringing it with the push-away, so I

have gone to the stringer. Sissy, maybe, but it works.

Hill Company has suggested the stringer too, incidentally.

As for arrows, the plain old cedar shaft is still mighty

good in the longbow, but I have successfully fired all

types of materials. The quick recovery of the cedar shaft

is hard to beat. Remember, the arrow has to, in fact,

dart around the riser of the bow and then spring back

into the line of arc. Therefore, the resilient cedar shaft

is a good one. I was surprised to see the true all·graphite

shaft work well, too. The shaft was a Lamiglas, which

is not part graphite, but all graphite.

Only these two arrows were used for shooting, as I had a

dozen of each around. The cedars were trimmed to twenty-

eight inches from the inset of the nock to the very tip of the

arrow and then the arrow was drawn back until the tip rest-

ed full on the shelf.

As for the Lamiglas arrows, they were left full length as

they are so very light anyway, and contrary to what we might

think, the longer pure graphite arrow is stronger than a short-

er pure graphite arrow. At least, this is what I am told by an

engineer who is in the business. Therefore, I have left my

graphite arrows at a full thirty-one-inch draw. With my favorite

compound I have trained myself away from the long 31 1/4 inch

draw I used to have, down to a more useful twenty-nine-inch draw.

I like a twenty-eight-inch draw in the longbow. We sometimes get

carried away with getting our equipment tuned and forget that we

can tune ourselves, too. Our bodies bend. And we can change a

draw length to some degree. It is no trouble to relax into the longbow,

lean into it, bend the elbow and enjoy a nice twenty-eight-inch draw

and the resulting lighter stiffer arrow.

The cedar arrow attained a velocity or 176 feet per second (fps).

This arrow, however, was a shade overweight for

the bow, being an Acme premium cedar in 70/75-pound

spine. l might have gotten the bow to stabilize well with a

65/70 spine, or even a 60/65 for a target arrow, though the

latter would probably be overcome by a heavy hunting head.

The Acme 70/75 weighed 497.5 grains.The stiff and ultra·light

pure graphite Lamiglas shaft

earned a starting velocity of 192 fps, this arrow weighing

only 434.2 grains. The stiffness and lightness seemed excel-

lent out of this bow, however, and it is a tribute to a good

arrow.

The nocking point was set on the bow by testing, not by

measuring first and then arbitrarily setting it, l simply put

the nocking point so that the arrow was perfectly horizontal

to start with and I moved the nock up on the string just a

little at a time until l was rewarded with a stabilized flight

out to forty yards and beyond. The greatest shooting I did

with the bow was at forty yards.

The arrows were, as per necessity, feather fletched. A

plastic vane will hit the shelf and toss the arrow askew. The

feathers simply fold back on the shelf and allow the arrow

to continue on its path. Unlike the testing of a compound,

the bow was shot “out of the box.” In other words, tuning

was not questioned. The longbow can be tuned, of course, by

changing the weight of the string, or by switching string

length to change fistmele. In short, by manipulating the

variables one at a time and checking arrow flight. Arrow

swapping is in itself bow tuning. But that is another story.

A glove was used, not a release of any kind. That’s nothing

new for me as l use a glove for all my testing, feeling that I

want to know the performance of the bow in the hunting

field as I would use it there. The glove will indeed slow down

the arrow to a small degree, however, and in all fairness this

should be pointed out. I have, in some compounds, picked

up several feet per second by going to a release, but usually,

in an overall contest, a smooth good glove won’t be that far

behind the velocity delivered by a release mechanism.

The newcomer to the longbow, especially the compound

shooter, should relax and enjoy this addition to his sport.

I call it an addition because I shoot both compounds and

longbows. And he should not go too heavy in draw weight.

It’s unnecessary for the most part when targets and deer-

sized game is going to be the main use of the bow. A fifty-

pound longbow will give a lot of pleasure, and when the

shooter builds up to it, a sixty or seventy will do a great

deal of work. If an archer is dedicated enough to spend

time in the back yard, he can build up to a lot of weight

and handle it well. Men of slight build can do it. I have a

shooting acquaintance who is small of stature, yet he fires

an eighty-six-pound longbow with ease and control. Unfortunately,

this peak can be lost if practice is forsaken. You’ve

got to keep in shape.

At the beginning of Winter, l am pretty strong with my

own seventy-pound longbow. By the beginning of Spring,

when Winter has denied me much shooting time, I’m pretty

bad. l should have an identical longbow to my seventy-

pound model that draws about forty-five or fifty to build

up with for the start of the new season each year, or move

to a civilized locale where shooting all year long is possible.

The Howard Hill Company Big Five bow sells, as this is

written, for $l79.95 plus F.E.T. (Federal Excise Tax) and

shipping. A letter to the company at N.W. 219 Blodgett

Camp Road, Hamilton, Montana 59840, will bring a price

list, plus a little catalog of the Howard Hill Company’s bows

and products, as well as some interesting information on

Hill himself. The company also sells arrows, gloves, arm-

guards, strings and other supplies to accompany the bow, all

in the traditional Hill format. And they also offer a few

books to help the archer, such as The Complete Archery

Book by Hochman and Longbow by Hardy.

The longbow, unlike the over-the-counter recurve, has

continued with a rather large following. It’s history is an

extremely interesting one, and a very long one, with no end

in sight, which is the way we would hope to have it. It is

good that an archer can select from different bow styles,

compounds, recurves and longbows, giving him that much

more scope to make his sport that much more interesting.

– Sam Fadala

ARCHIVED BY

www.ARCHERYTALK.com

All Rights Reserved

Your Privacy Choices

Your Privacy Choices