Published by archerchick on 22 Mar 2010 at 11:57 am

Oneida Eagle – By Norb Mullaney

Oneida Eagle–by Norb Mullaney

February 1983

It may not feature pleasing lines, but it sure is one sweetheart of a bow

Long before anyone gave any thought to a compound bow, the principle of the recurved limb was used to increase the tension in the bow string in the early stages of the draw. This was possible

because the recurve effectively shortened the limb moment arm thus requiring a higher draw force to bend the limb in the initial draw.

Many bow designs employed non-working recurves in the limbs – recurves that did not bend to any significant degree when the bow was drawn. Subsequently, modern recurve design went almost entirely to the working recurve. By permitting the recurve to flex along with the rest of the limb it is possible to obtain a smoother drawing bow and greatly reduce stacking in the later stages of the draw.

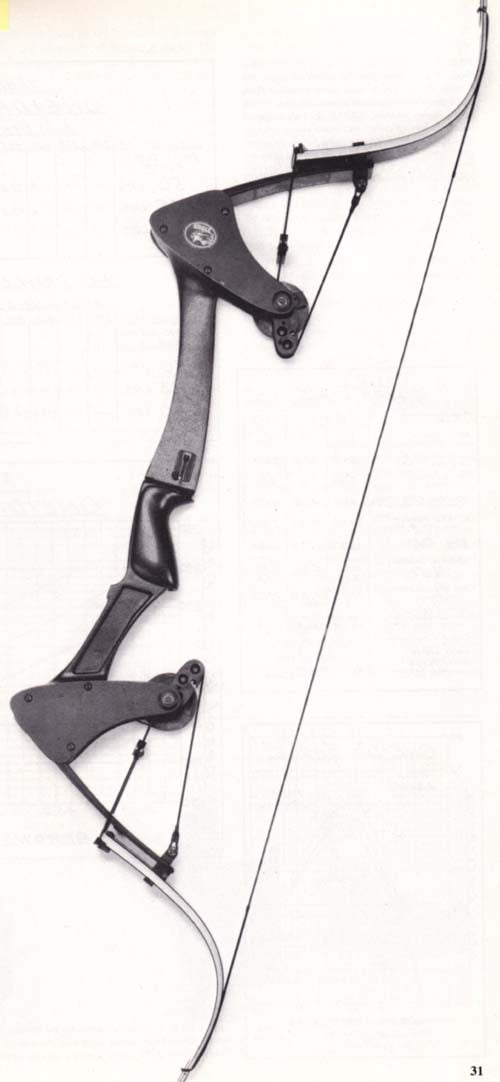

John Islas’ Eagle, manufactured by Oneida Labs of Canastota, NY, employs non-working recurve limb sections of composite laminated construction, in conjunction with short, solid, tapered F.R.P. power limbs, programmed cams, and a synchronizing system. All of these power and control elements are blended together to produce one of the smoothest shooting, high performance bows that we have tested to date.

In establishing the geometry for a bow it is common practice to locate the center of pressure of the grip on the horizontal centerline of the handle-riser. The Eagle has the center of pressure about two inches below the centerline so that the centerline is actually slightly above the shelf and closer to the point of arrow passage. It can be argued that this arrangement offers a more balanced distribution of push and pull forces along the vertical axis of the bow.

The handle-riser is a magnesium alloy casting with a decided reflexed geometry. The structure has a full length vertical groove on the string-hand side to accept the synchronizing or timing cables. This arrangement relocates the usual crossed cables of most compound bows so that there is no chance of interference with arrow shaft or fletching and, obviously, no need for a cable

The handle-riser is a magnesium alloy casting with a decided reflexed geometry. The structure has a full length vertical groove on the string-hand side to accept the synchronizing or timing cables. This arrangement relocates the usual crossed cables of most compound bows so that there is no chance of interference with arrow shaft or fletching and, obviously, no need for a cable

guard. The shooting string is located in the plane of the vertical centerline of the bow just as for a straight or recurved bow.

A molded slip-on grip is provided. This grip bridges the cable groove where the hand contacts the handle. The usual AMO standard mounting provisions are provided for bow sight, quiver and stabilizer. The riser is drilled and tapped for a cushion plunger. Very early Eagle bows had this hole positioned too close to the shelf, causing some interference with vane fletching. This has subsequently been raised and is no longer a problem.

At each end of the handle riser a pair of aluminum alloy sheet brackets extend from the face of the bow angling toward the center. These pylon brackets carry the programmed cams and synchronizing pulleys which are tied together and mounted on the same axle. In this manner, the programmed cams are forced to synchronize and thus cause the limb systems to operate in unison. An adjustment slot is provided on the upper synchronizing wheel for exact timing between upper and lower limb systems. The short, solid power or working limbs are fitted with half-cylindrical bearings that rest in receptacles in the ends of the handle riser. Socket-type flat-head limb adjustment bolts are used with countersunk washers to retain the limbs. These power limbs are set at an angle close to thirty degrees to the horizontal, so that most of the flexing action is

At each end of the handle riser a pair of aluminum alloy sheet brackets extend from the face of the bow angling toward the center. These pylon brackets carry the programmed cams and synchronizing pulleys which are tied together and mounted on the same axle. In this manner, the programmed cams are forced to synchronize and thus cause the limb systems to operate in unison. An adjustment slot is provided on the upper synchronizing wheel for exact timing between upper and lower limb systems. The short, solid power or working limbs are fitted with half-cylindrical bearings that rest in receptacles in the ends of the handle riser. Socket-type flat-head limb adjustment bolts are used with countersunk washers to retain the limbs. These power limbs are set at an angle close to thirty degrees to the horizontal, so that most of the flexing action is

vertical rather than forward. This is one of the reasons that this bow has little or no recoil action.

The recurved limbs feature conventional laminated composite construction with significant double taper. Hinge mechanisms with the hinge pins located three inches from the butts of the recurved limbs, attach these limb elements to the tips of the power limbs. In this manner the two limb elements actually overlap for three inches, with a lever arrangement established that can vary from from about 1 to 1 to close to 3 to 1 as the bow is drawn and the recurved limb pivots. Review of the accompanying photographs will clarify this verbal description. The rigging arrangement is also unique. A double, uncoated 3/32 inch diameter power cable runs from the hinge bracket assembly at the tip of the power limb to the two center grooves on the four groove programmed cam. It is retained in the cam by a transverse roll pin. A second double cable assembly (1/16

inch diameter-coated) is anchored in a transverse hole in the cam and threaded in the two outer cam grooves or tracks. It is spread by a special yoke clamp to clear the power limb and is then looped over a molded fitting that is bolted to the extreme butt end of the recurved limb.

The limb and cam action works as follows:

1. Force is exerted on the tip of the re-

curved limb by the act of drawing the bowstring.

2. The recurved limb pushes against the

power limb at the pivot axle and also pulls

on the yoke cable. This combined action starts

the cam to rotate toward the handle-riser.

3. As the cam rotates, the cam lever ratio changes,

requiring more force from the yoke cable to bend the

power limb. However the lever ratio of the recurved

limb has been increasing at the same time. This

counteracts some of the effect of the change in cam ratio.

4. The net result is a rapid rise to peak draw force. At

this position the oblong cam is centered angularly between

the power cable and is just about ready to roll over.

5. Further draw on the string moves the cam past center

and let-off begins.

6. Let-off continues until the cam rotates to the point

where the power cables lie in the flat sections of the

grooves at the inner ends of the cams. At this point the

bowstring is perpendicular to the tip section of the recurved

limb and a bottoming condition is established.

Other bows carrying the cams on the handle-riser have employed a simple figure eight cable loop connecting the synchronizing pulleys. This leaves the cable exposed close to the riser and generally necessitates offsetting the pulleys to provide cable clearance. On the Eagle, John Islas has provided for routing the synchronizing cables through the handle-riser using a pair of idler pulleys located between the pylon plates. These idlers are mounted on axles set in lugs which are integral with the risers. The idlers are located tangent to the cable groove. The cables run

from the synchronizing pulleys, over the idlers, and through the groove to establish the

timing loop.

It should be understood from the foregoing that the recurved limbs are just as much a part of the force-draw characteristics as the programmed cams and the normal limb-string geometry of the bow as it is drawn. The recurves shorten the moment or lever arms of the secondary limbs, assisting in obtaining greater string tension at brace height and a steep initial slope for the force-draw curve. However, this desirable trait is also a function of the cam design. At brace height position, the cams have lever ratios also designed to promote high string tension.

It is important to recognize that the recurved limbs are very rigid and essentially non-working. Measurements taken across the distance from tip to butt varied only about one-eighth inch between brace height and full draw.

For the Eagle, the force-draw characteristic is a very complex function of string angle, recurved limb angle, instantaneous cam ratio and power limb angle and spring factor. All of these elements work together to provide the highly effective and very smooth force-draw curve.

The Eagle uses a straight forward shooting string much like a recurve bow, except that it must be strong enough to withstand the stress imposed by the high level of energy generated.

At the present time this bow is available in a single adjustable draw weight range of 45 to 65 pounds. Draw length can be obtained in four nominal ranges; 28 to29,29 to 30, 30 to 31 and 31 to 32 inches. At the factory, draw length variation is effected by modifying the recurved limb bolt hole pattern and changing string length. For short draw lengths a change of cam is required.

The spreader yoke can function as a positive draw check or stop if desired. It is a simple operation to set it and this does not affect the geometry of the yoke cable. The socket-head cap screw that clamps the yoke is loosened and the yoke is repositioned to bottom against the face of the power limb at the desired maximum draw length. A strip of pressure sensitive tape can be applied to the limb at the line of contact to prevent marring. Care should be exercised to bottom both yokes at the same draw position. A left-hand model is planned but is not yet available.

Admittedly an unusual looking bow, the Eagle is cleverly designed and well-built with

evidence of thoughtful engineering throughout.

The Tests

The Eagle we have had for test was rated 45 to 65 pounds draw weight with a draw length

of 29-30 inches. It was equipped with a cushion plunger and a flipper rest which were used for all test shooting. Preliminary hand shooting revealed several surprising characteristics that would require thorough investigation during the test program. First, at 60 pounds this bow seemed as easy and pleasant to draw as any compound we have tested. Second, it was remarkably smooth during the power stroke with almost imperceptible recoil action. Third, even without the aid of chronograph verification a high level of performance was obvious.

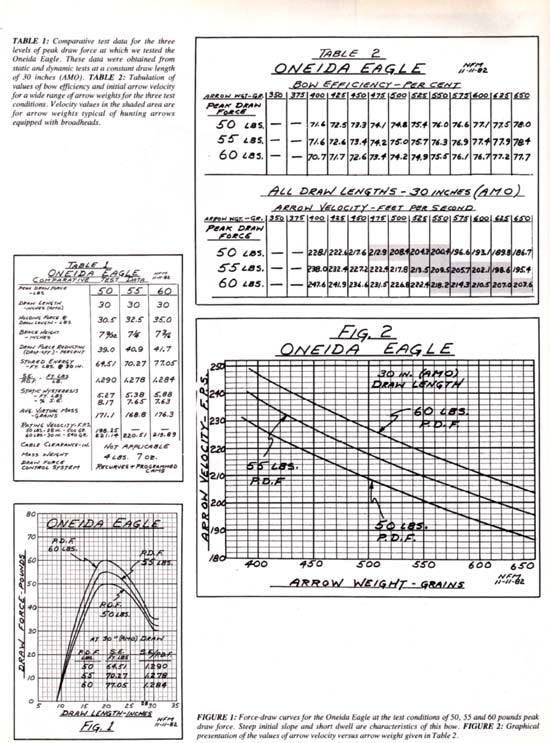

Our test program was established for three levels of peak draw force; 50, 55 and 60 pounds, with a common draw length of 30 inches (AMO). The static tests always give a good indication of what we can expect in the way of performance – the Eagle was no exception. Fig. I displays the force-draw curves we obtained for each of the test conditions. In a number of ways these curves differ from both the conventional (eccentric type) and the programmed cam characteristics. Like the programmed cam they reach peak draw force early in the draw cycle (about 12 inches) but they do not have a lengthy dwell. The longest dwell is two inches at the 50 pounds P.D.F. level. Beyond the peak, the let-off is similar to a conventional eccentric with a very precise and consistent bottom between 30 and 31 inches draw (AMO).

The let-off varied between 39 and 41.7 percent, increasing slightly with increase in

draw weight.

The design of these force-draw curves is such that the draw seems exceptionally smooth and unstraining, so that it leaves one somewhat unaware of the amount of stored energy that is being generated. However, note the tabulated values of stored energy and the S.E./P.D.F. ratio. They are noticeably higher than for conventional compounds and rival the values we associate with programmed cams. This is a forecast of the performance we cited previously.

Static hysteresis is a measurement of the friction in the compounding system. The Eagle shows about two percent higher than a typical two-wheeler in this characteristic. It isn’t difficult to pinpoint the cause. Running the synchronizing cables through two ninety degree bends (idler pulleys) and also through the handle-riser will account for more than two percent. The basic cable system must be quite efficient.

Table 2 is a tabulation of values of bow or dynamic efficiency and arrow velocity for a wide range of arrow weight for each of the three test conditions. Curves of the arrow velocity given in Table 2 are plotted in Fig. 2.

Bow efficiency is the initial kinetic energy of the launched arrow expressed as a percentage of the stored energy of the bow. It is a measure of just how well a given bow transfers to the launched arrow the energy required to draw it to the specified draw length. We have generally found that the very high performance programmed cam bows have lower efficiency than we find for the better class of two-wheel compounds using circular eccentrics.

We do not attribute this general trend (which ranges from minus three to minus ten percent) entirely to characteristics inherent in the bow. There is significant evidence to argue that some of it is caused by losses involved in transferring the higher level of energy to the arrow and to increased reaction forces on the arrow. The Eagle demonstrates minimum efficiency loss when compared to the better two-wheelers with eccentrics. This is also obvious in the arrow velocity levels obtained in the machine shot and chronographed tests. Despite its easy-drawing feel it achieved a Rating Velocity (60 lbs.-30 inches-54O grains) of 219.89 feet per second. Using mathematical synthesis we also calculated relative Rating Velocities at the 50 and 55 pound levels. These showed slight improvement when compared to the 60 pound peak draw force. This can be attributed to slightly improved bow efficiency and energy storage ratio as draw weight was reduced.

For those readers familiar with our prior Rating Velocity standard of 50 pounds-28 inches-500 grains, we also computed that rating at the 50 pound test level. At 198.25 feet per second it is nearly 10 feet per second higher than the best eccentric two-wheelers we have tested.

Without question the Eagle merits placement in our “super performance” category. But beyond that, we must also salute it as exceptionally smooth and pleasant shooting.

General Commentary

As with other programmed cam type high performance bows, we found that the Eagle favors heavier and stiffer arrows. At 60 pounds P.D.F. we obtained good launch and flight from Graphlex Yellow and 2216 aluminum shafts up to 30 inches draw length. This included field points as well as broadheads of various types. We liked 2117 shafts at 55 pounds and 2117 and 2018 shafts at 50 pounds. Release shooters may be able to stretch these poundages somewhat but we could not obtain consistently clean launch and flight with lighter shafts than those cited.

We have already commented on the remarkable smoothness of the Eagle in both draw and release. It is also a relatively quiet bow.

Because of its unusual limb action. the string angle at full draw is more acute than on other 48 inch bows. This means that there is more finger-pinch present. We didn’t find it objectionable at 30 inches draw; however, it is inherent in the bow design. Also inherent in the limb design and action is unusual stability and tiller control. We felt that it seemed quite resistant to bow hand torque.

Perhaps the Oneida Eagle is an odd looking bow. Its only claim to grace and beauty may be the recurved limbs, unless you’re an engineering type who perceives beauty in function and mechanism. But we suggest that you reserve comment until you have an opportunity to shoot this bow. We believe it has a combination of fine shooting qualities that are rare indeed.

Archived by

ARCHERYTALK.COM

all rights reserved

Leave a Reply

You must be logged in to post a comment.

Your Privacy Choices

Your Privacy Choices